Languages

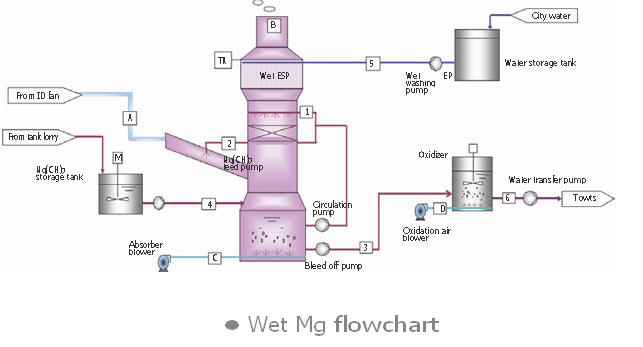

Wet Mg

Wet Mg/Na FGD Process

The wet scrubbing method using the magnesium hydroxide (Mg(OH)2) or sodium hydroxide (NaOH) . An optimal process with a proven track record, it uses Mg(OH)2 or NaOH solutions to circulate flue gas from boilers to remove SO2 and dust through gas-liquid contact.

Higher SO2 removal efficiency can be achieved by increasing the pH and SO3 2- levels of the sorbent. The higher the pH level, the sharper the decline in the solubility of MgSO3. Due to this phenomenon, sedimentation of MgSO3 may occur. To prevent clogging caused by sedimentation and to optimize desulfurization, it is important to control the pH and SO3 2- levels of the sorbent. The optimal level is determined by the exit SO2 concentration from the absorber.

In general, the pH level of the sorbent should be 6.0 ~ 6.5 and the SO3 2- ion concentration should be below 0.1 mol/L. The SO3 2- level of the sorbent is controlled by adjusting the amount of oxidation air.

Advantages

- Easy operation and maintenance

- Simple structure and compact size

- Proven track record

Projects

- Jeju Power Plant Units 1~2, Korea (2004, 2009)

- BLCP Thermal Power Plant, Thailand (2005)