Languages

eBFTM

eBFTM, electrostatic Bag Filters

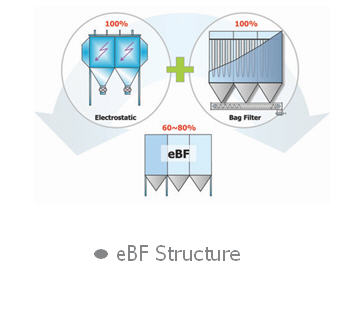

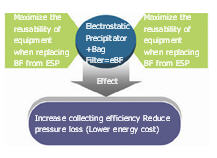

Featuring a charging device installed before flue gas passes through the bag filter, the

electrostatic bag filter is designed to lower equipment and operating cost compared to using only a bag filter. It combines the benefits of the ESP and bag filter.

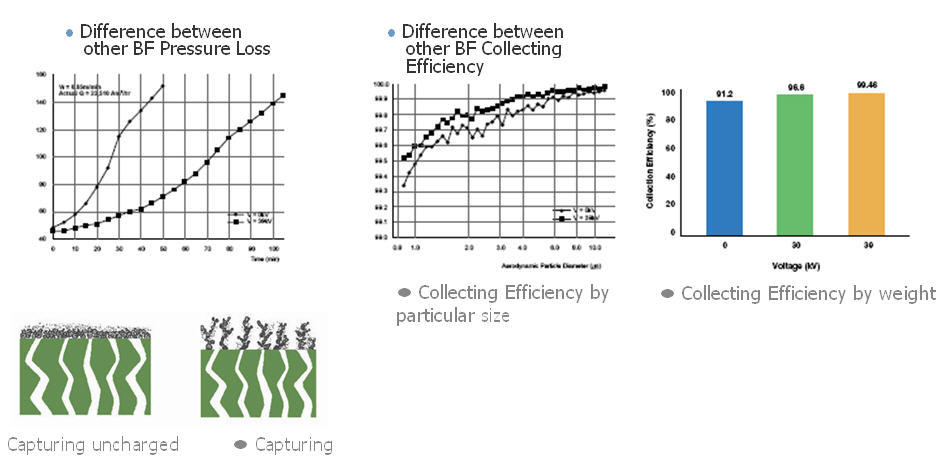

Electrostatic force is used to address the increase in pressure loss, a problem associated with conventional bag filters. Electrostatically charged dust particles form a dendrite layer on the filter surface which prevents fine particles from penetrating into the filter and reduces filter clogging. Electrostatic bag filter is a high performance dust collection system with enhanced collection efficiency.

Advantages

- Formation of dendrite layer of dust by using electrostatic force

- Less clogging by preventing fine particles from penetrating into the filter

- Enhanced collection efficiency

- Less friction loss due to increase in filtration surface

- Reduced pressure loss

- Increase in filtration speed and amount (assuming identical facilities)

- Longer filter lifespan due to longer dust removal cycle

- Low initial investment and operating (energy) cost

Projects

- Yeongwol Plant Units 3, 5, Ssangyong Cement, Korea (2003)

- Lime Conveying Line, Dangjin Thermal Power Plant, Korea (2007)

Korea Patent No. : 0227127 (Registration Date 30th July 1999)

* Capacity Certificate No. : 15-386, Small and Medium Business

Administration in Korea (Date of issue 7th May 2008)

Trapped particles gain properties of an electrostatic filter due to polarity of the filter. As a result, particles are also captured by already trapped particles. Particles branch out in the shape of twigs as they collect dust.

- Less pressure drop, savings in maintenance and energy cost, longer filter lifespan