Languages

SCR

SCR(Selective Catalytic Reduction) Process

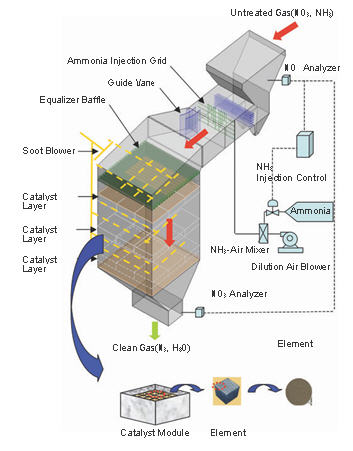

SCR technology enables reduction of nitrogen oxide even with low activation energy by passing flue gas through a catalyst layer after mixing a reducing agent. The SCR process uses a catalyst that selectively reacts with nitrogen oxide in flue gas. It has the highest removal efficiency among de-NOx technologies and stable operation.

Advantages

- High NOx removal efficiency (over 90%)

- Minimal NH3 slip due to use of optimal amount of reducing agent

- Operation at high SO2 concentration

- Low conversion rate of SO2 to SO3

- Equipped with device for even flue gas distribution into the reactor

- Regular catalyst activation test and reporting

- Savings in catalyst replacement cost due to catalyst regeneration and reuse

- Optimal reactor design using CFD

- High quality technical service

- Ease in injecting and decomposing catalyst

Reducing agents & Types of Catalyst

- Reducing agents : Anhydrous ammonia, Aqueous ammonia, Urea solution

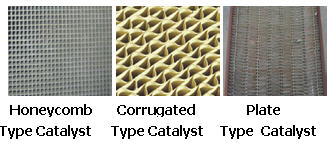

- Catalyst : Formation V2O5/WO3/TiO2

Projects

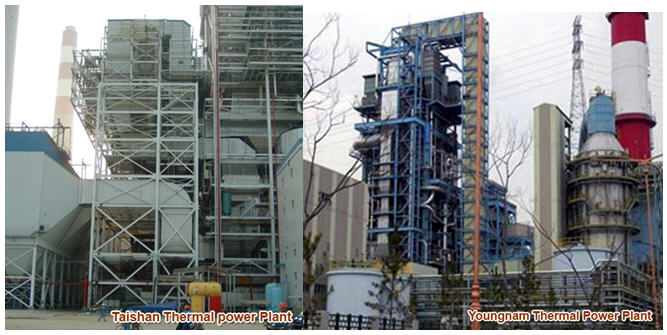

- Dangjin Thermal Power Plant Units 1~4 500MW X 4, Korea (2006)

- Taishan Thermal Power Plant Unit 5 600MW, China (2006)

- Gwangyang Ferronickel Plant (POSCO), Korea (2007)

- Gwangyang Sintering Plants 1~4 (POSCO), Korea (2008)