Languages

General information

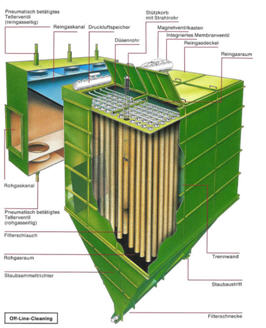

Fabric filters remove dust from a gas stream by passing the stream through a porous fabric. Dust particles from a more or less porous cake on the surface of the fabric. It is normally this cake that actually does the filtration.

The manner in which the dust is removed from the fabric is a crucial factor in the performance of the fabric filter system. If the dust cake is not adequately removed, the pressure drop across the system will increase to an excessive amount. If too much of the cake is removed, excessive dust leakage will occur while fresh cake develops. The selection of design parameters is crucial to the optimum performance of a fabric filter system.

Fabric filter systems are frequently referred to as baghouse, since the fabric is usually configured in cylindrical "bag". The two most common baghouse designs are the reverse air and the pulse jet types. These names describe the cleaning system used with the design.

Reverse air baghouse operate by directing the dirty flue gas into the inside of the bags, therefore, the collection of dust is on the inside surface of the bags. The bags are cleaned periodically by reversing the flow of air, causing the previously collected dust cake to fall from the bag into a hopper below. Since this cleaning procedure is accomplished at relatively low gas velocity, the fabric is not exposed to violent movement and so the reverse-air cleaning technique normally results in maximum bag life. In variation of reverse-air baghouse design and the forerunner of the reverse-air baghouse, the baghouse are shaken during the reverse-air cleaning interval.

Pulse-jet baghouse are designed with internal frame structures, called cages, to allow collection of the dust on the outside of the bags. The dust cake is periodically removed by a pulsed jet of compressed air into the bag causing a sudden bag expansion; dust is removed primarily by inertial forces when the bag reaches its maximum expansion. This bag cleaning technique and frequently the bag to cage fit tend to limit bag life and also tend to increase dust migration through the fabric, thus decreasing dust collection efficiency.